R+D+I

R

RESEARCH

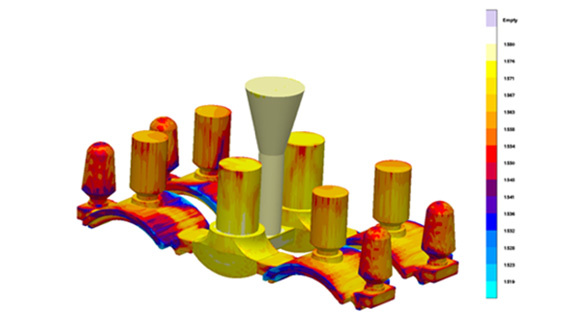

FUNORSA has an engineering team that studies the possible improvement to be made in the fundamental processes of the foundry, such as feeding systems, sand and materials.

We have the latest technology for casting simulation and material analysis for this purpose. This, together with the experience of our technicians, allows us to introduce improvements in the quality of the parts and in the optimization of the production process.

D

DEVELOPMENT

As a result of research, FUNORSA has developed manufacturing processes so it can offer its customers complex parts with the required quality standards at a competitive price.

FUNORSA’s engineering and manufacturing teams constantly seek to improve production methods to offer their clients solutions from a technical and economic point of view.

I

INNOVATION

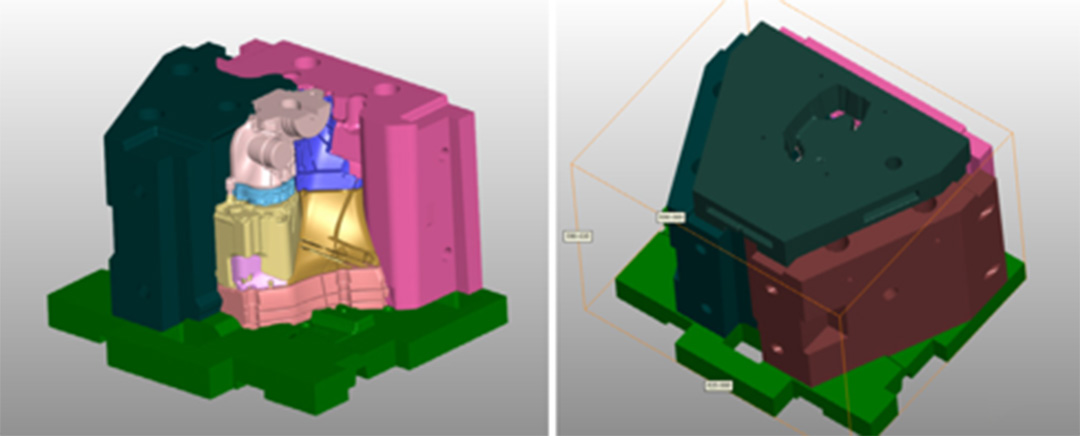

Innovation is the fundamental axis of FUNORSA’s strategic development for the coming years. The manufacture of 3D additive printing sand molds is one of the innovation segments in which FUNORSA is investing.

This innovative system allows the manufacture of cores and sand molds by printing compared to the traditional system of molding by means of pattern, being the most suitable for the making of prototypes, spare parts and short series in which the investment in pattern is a factor against both its high cost and delivery time.

Among other advantages of this new molding method are the greater geometric precision and the possibility of manufacturing pieces of greater complexity, the ease of making modifications in the design and the improvement of the features of the pieces.