Processes

FUNORSA PRODUCES HIGH REQUIREMENT MOLDED STEEL PARTS IN A RANGE OF 10 KG TO 1,200 KG IN PEPSET CHEMICAL MOLDING. (SPECK MOLDING)

01

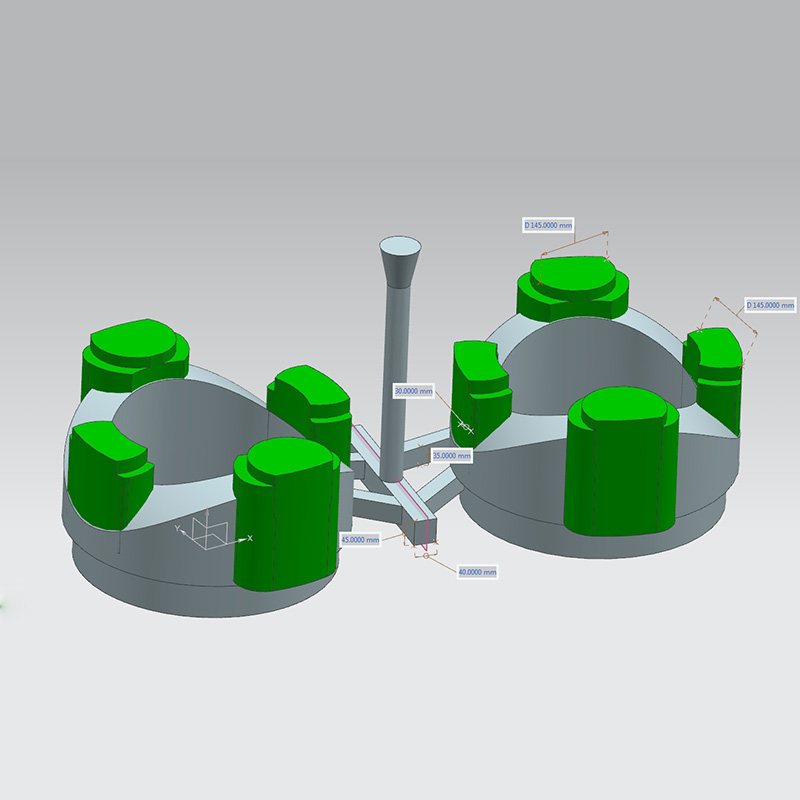

ENGINEERING

FUNORSA carries out the complete development of the project in all its phases:

-

Casting simulation.

-

Calculation and design of feeding systems.

-

Process design.

-

Establishment of control guidelines.

-

Proposal of efficient designs.

02

Patterns

The manufacture of wood and resin patterns is made in specialized workshops authorized according to our indications and quality control.

03

Pouring

FUNORSA has 2 induction furnaces with a capacity for 2,000 kg of melted product.

04

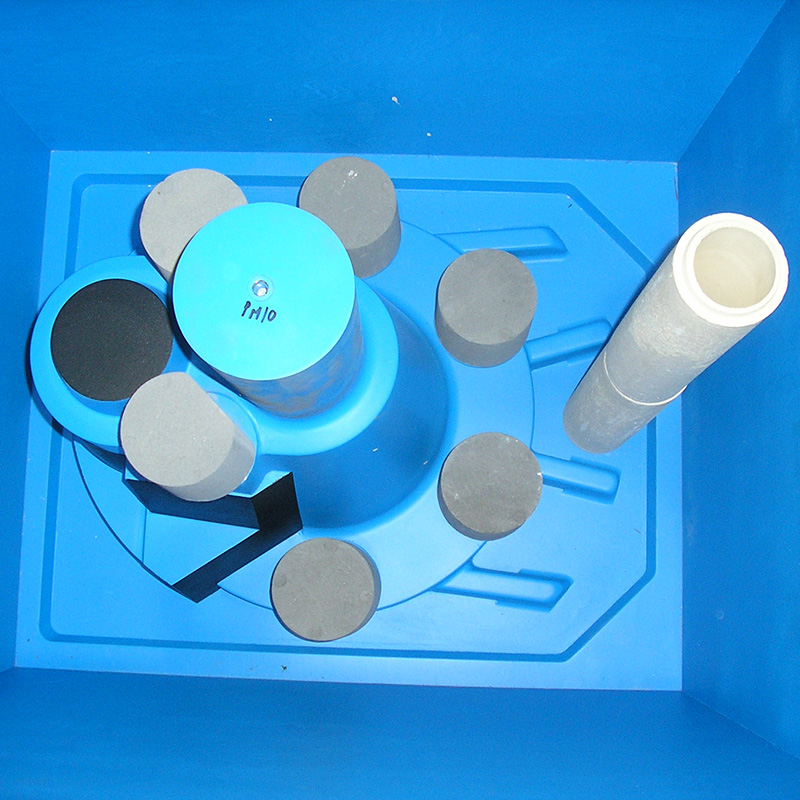

Moulding

FUNORSA has two lines of PEPSET chemical molding in speck:

-

A semi-automatic line with a maximum speck size of 1.200mm x 1.500mm.

-

A manual casting line with a maximum speck size of 2.500mm x 2.500mm.

-

Two automatic sand mixers.

-

A core shooting machine.

-

A thermal sand reclamation plant.

-

A vibrating table for the demolding of the pieces.

05

Finishing

In order to proceed to the correct finishing of the pieces FUNORSA has the following equipment:

- Two shot blasting machines.

- A cutting area.

- A deburring area.

- A hydraulic press.

- A quality control and inspection area.

06

Heat Treatment

FUNORSA owns a gas furnace for the heat treatment of the pieces, with a capacity of 10 tons.

07

Machining

FUNORSA has a network of approved machining workshops to offer its customers fully finished parts.

08

Other Processes

FUNORSA offers other processes as part of its scope of supply.

-

Painting.

-

Galvanization.

-

Assembly.

-

Weld.

-

Reverse engineering.

-

Pressure testing.